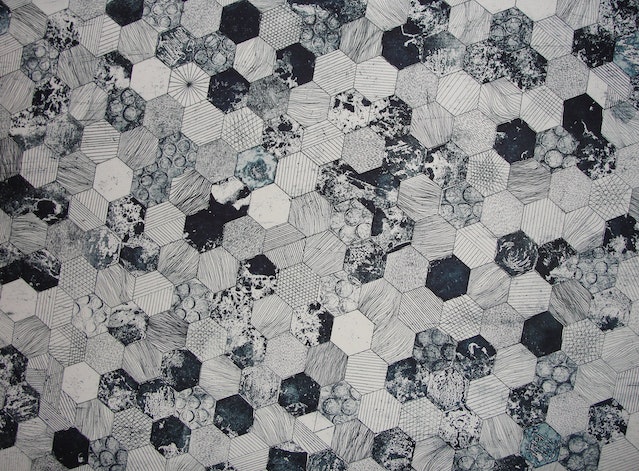

Surface Impurities

Tile is a manufactured furnishing material commonly used to cover walls, ceilings and floors in any interior space. Not only is it functional, but tile can add color, texture and dimension to a space with its wide array of styles including ceramic tile, glass mosaic tiles and marble mosaic tiles – not forgetting its durability in resisting moisture!

Tiles can become subject to many defects that compromise their appearance, such as buckling of tiles, surface cracks or shade variations. To avoid such issues, it is crucial that inspection of tiles take place prior to their installation.

Porcelain tile, ceramic and natural stone are three popular choices of tile that are popularly used. Porcelain is produced from clay that has been heated at high temperatures; this dense material has low water absorption rate making it suitable for high traffic areas. Ceramic and porcelain tiles come in various sizes from half inch squares up to two foot squares making this type of material versatile enough to meet all your needs.

To be considered porcelain tile, a tile must meet certain ASTM C373 water-absorption standards. To be certified porcelain by the PTCA and maintain their certification status every three years. However, self-policing organizations such as this aren’t always effective as dishonest companies can falsify test results to stay ahead of competitors.

Ion Fluxes

Tiles are thin plates used to cover surfaces like walls, floors and roofs. Available in various shapes and finishes to create various designs and styles, tiles typically made up of clay material but today also consisting of recycled material materials to be more eco-friendly.

Weather conditions can have an effect on ion fluxes in tiles, with stormy conditions increasing fluxes due to heating caused by MS waves and trapped warm ions in a density cavity, while less stormy conditions reduce it as cold ions become less confined and decrease fluxes accordingly.

Another factor influencing ion fluxes is how tiles are processed to achieve their surface appearance, including smooth, glossy or matte finishes as well as hammered, honded and textured options. Not only will a tile’s finish affect how it looks in a room but it may also impact its durability and strength over time.

Terracotta tile is made by pressing together various clay mixtures into various forms before drying and firing them, giving rise to its characteristic earthen tones and color range. Terracotta comes in various shades and finishes and can be laid in patterns such as herringbone and chevron for maximum effect. Terracotta is durable, water resistant and thermal insulating; making it the ideal choice for bathrooms, patios and fireplace surrounds.

Mechanical Measurements

Tiles are manufactured from earthen materials processed under high pressure and extremely hot temperatures, creating porcelain tiles. The manufacturing process creates hard-wearing material with low water absorption rates that is suitable for interior applications including kitchens and bathrooms.

Surface texture of tile has an enormous effect on the look and feel of any space, as the finish can range from matte, semi-polished, glossy, hammered or honed finishes – the texture may also create contrast within colors; serve as design element or even add slip resistance in commercial floor applications.

Size and shape are crucial considerations when selecting tiles for any space, from small spaces like bathrooms to open environments such as atriums. Tiles come in an assortment of shapes and sizes so it should be easy to find something to match the style of your space.

An environmental life cycle assessment (LCA) was performed on eco-Terrazzo tiles made with marble granulate, cement and pigments in their single layer (SL), as well as quartz sand and cement for their double layer (DL). These tiles boast improved sound quality with reduced environmental impacts compared to traditional Terrazzo tiles.

SIMS

Tiles are an increasingly popular surface furnishing choice. Available in various forms and sizes – from tiny half-inch square mosaics to 2-foot square tiles – tiles can be found everywhere from tiny half-inch mosaics up to 2-foot square tiles made of any hard material such as stone, glass, metals or ceramics; with some even being produced using recycled materials!

Tile 8 NRA and RBS both displayed a surface film with modest 13C concentration, which has persisted since the first experimental QMB run, seemingly due to chemical re-sputtering of Be by deuterium (D) ions; however, due to lack of energy from D ions they cannot physically sputter away W from plasma boundaries resulting in low fluxes at edge of last closed flux surface (LCFS).

Drilling was performed every 20 mm to create cross-sectional analysis samples from 17 locations for further examination with an optical microscope, with results showing very uniform distribution of deposits with some areas having higher Be/C ratios nearer to the surface.

Tile 3 deposits were thicker than Tile 1 deposits, reaching 60 mm thickness as shown by the polished cross section in Fig 32. This was due to both increased deposition and reduced erosion due to re-sputtering from Tile 1.

Universal Agency

Universal Agency in Erode is your one-stop destination for high-quality tiles that redefine interior spaces. With a stunning showroom featuring an extensive range of tiles, from classic to contemporary designs, we offer an array of options to suit every style and budget. Our expert in tiles showroom is committed to assisting you in selecting the perfect tiles for your residential or commercial projects. Whether you’re looking for elegant porcelain tiles, durable ceramic tiles, or stylish mosaics, we have it all. At Universal Agency, we’re not just about selling tiles; we’re about helping you transform your spaces into works of art.